BIM for MEP & FP Designers: Establishing Precision, Sustainability, and Collaboration in Building Services

In the intricate world of MEP & FP (Mechanical, Electrical, Plumbing, and Fire Protection) design, the margin for error is razor thin. Even the slightest miscalculation in these interconnected systems can cascade into costly delays, safety risks, and inefficiencies. Enter Building Information Modelling (BIM)—a disruptive force that is not just refining but revolutionising how MEP & FP systems are designed, coordinated, and executed.

From CAD to BIM: The Evolution of Design Paradigms

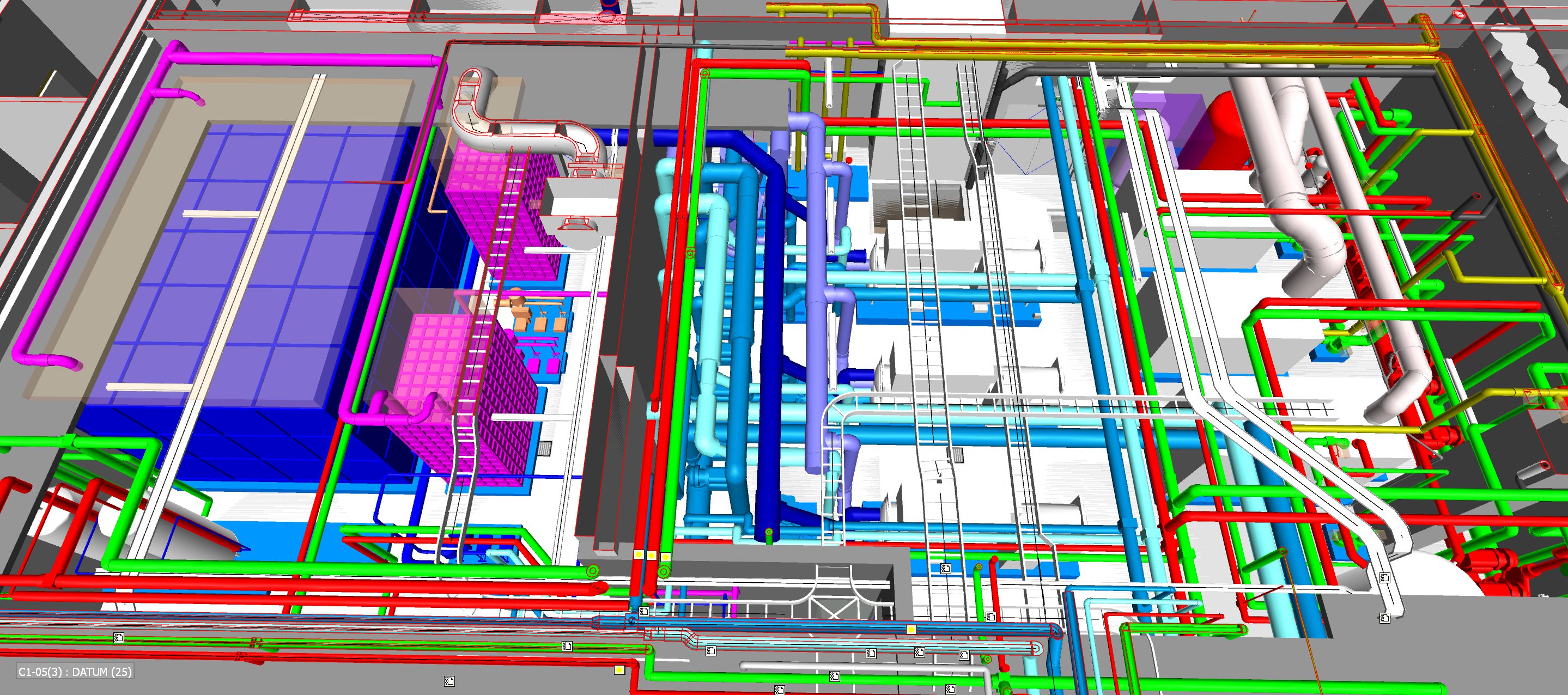

Traditional CAD workflows provided static, two-dimensional outputs, limiting designers’ ability to visualise and anticipate real-world challenges. BIM takes this process to an entirely new dimension—literally. By creating a dynamic, data-rich 3D environment, BIM allows MEP & FP designers to analyse and optimise systems in ways CAD could never achieve.

The transition from CAD to BIM is more than a technological shift; it represents a paradigm change in how we approach building services design. With BIM, the focus is on integration, data sharing, and real-time collaboration, enabling designers, contractors, and clients to work from a single source of truth.

The Multi-Dimensional Advantage: How BIM Serves MEP & FP Design

1. Clash Detection and System Coordination

MEP & FP systems are often the most congested and intertwined within a building’s infrastructure. BIM’s clash detection capabilities ensure that electrical conduits, ductwork, plumbing pipes, and fire suppression systems are perfectly aligned. Designers can identify and resolve conflicts at the planning stage, reducing rework and on-site disputes.

2. Lifecycle Analysis Through 4D and 5D BIM

Beyond 3D modelling, BIM integrates the dimensions of time (4D) and cost (5D). For MEP & FP designers, this means accurate scheduling of installation phases and detailed cost estimation for materials and labour. This holistic approach ensures that projects remain on time and within budget.

3. Performance Simulation and Energy Optimisation

BIM empowers designers to simulate real-world performance, from HVAC load calculations to fire suppression response times. Advanced tools like energy modelling help optimise system efficiency, ensuring compliance with green building standards such as LEED and BREEAM.

4. Compliance and Regulatory Adherence

In regions with stringent safety codes, BIM simplifies compliance by embedding regulatory requirements into the design process. Fire protection systems, for example, can be tested virtually for flow rates, sprinkler coverage, and smoke evacuation before physical installation.

Let’s take an example from one or two sectors to understand the applications of BIM in MEP and Fire Protection design.

Designing for a Smart Hospital

A healthcare facility requires ultra-efficient MEP & FP systems to maintain critical operations. Using BIM, engineers were able to integrate IoT sensors into HVAC and electrical systems, ensuring optimal temperature, lighting, and energy usage. Virtual simulations of air circulation reduced infection risks, and clash-free layouts minimised installation time in high-stakes environments.

Retrofitting a Heritage Building

Retrofitting an older structure poses unique challenges, especially when integrating modern MEP & FP systems. With BIM and Scan-to-BIM technology, designers can create accurate as-built models of the building. This allowed precise routing of ductwork and plumbing without compromising the historical integrity of the structure.

Challenges in BIM Implementation for MEP & FP

1. Steep Learning Curve

The shift to BIM requires significant training for design teams. Mastering advanced tools like Revit MEP or Navisworks takes time, but the long-term gains in efficiency and accuracy make the investment worthwhile.

2. Data Overload

BIM models are data-rich, which can be overwhelming for teams unaccustomed to managing such granular information. Employing data management strategies and using platforms like Autodesk Construction Cloud can streamline workflows.

3. Interdisciplinary Coordination

While BIM facilitates collaboration, it also requires every stakeholder—from architects to contractors—to adopt BIM processes. Misalignment in skill levels can create bottlenecks.

Looking Ahead: The Role of BIM in Sustainable MEP & FP Design

As the industry shifts toward net-zero carbon emissions, the role of MEP & FP systems in energy conservation is paramount. BIM enables designers to model renewable energy systems, optimise insulation, and reduce HVAC loads. The integration of Digital Twin technology further extends BIM’s capabilities, providing real-time monitoring of building performance post-construction.

For fire protection, BIM offers tools to design systems that are not only compliant but also resilient in the face of increasing urban density and climate challenges. The result? Safer, smarter, and more sustainable buildings.

BIM as the North Star for MEP & FP Designers

The construction industry is no stranger to challenges, but with BIM, MEP & FP designers are equipped to tackle them head-on. By embracing BIM, we are not just improving workflows; we are setting a new standard of excellence in building services engineering.

At Everest Technical Services, we believe in harnessing the full potential of BIM to deliver precision-engineered MEP & FP solutions. Our expertise ensures that every project—whether new construction or retrofit—meets the highest standards of innovation, sustainability, and safety.

Ready to redefine your approach to MEP & FP design? Let’s build the future together. Contact us today!